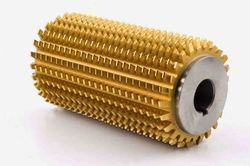

Multistart Cutters

Price 5000 INR/ Piece

Multistart Cutters Specification

- Features

- Wear resistant, High performance, Long tool life

- Length

- Up to 300 mm Millimeter (mm)

- Brooches Type

- Notch / Keyway

- Cutting Force

- Optimized for minimal cutting force

- Operate Method

- Automated/CNC & Manual compatible

- Coating

- Uncoated or customized coating as per requirement

- Drill Bits Types

- Helical / Spiral Fluted

- Cutting Speed

- 60120 m/min (depending on material) m/m

- Tool Type

- Multi-start Cutter

- Usage

- For Industrial Machine Use

- Cutting Capacity

- Designed for high volume chip removal

- Hardness

- 58-62 HRC

- Operation Type

- Grooving / Slotting / Thread Milling

- Shape

- Round with multiple cutting edges

- Cutter Type

- Multi-start / Helical cutter

- Machine Type

- Milling, CNC, Industrial machine

- Cutting Accuracy

- High precision up to 0.05 mm mm

- Coating Type

- PVD/CVD optional

- Material

- Stainless Steel

- Diameter

- 10 mm to 200 mm Millimeter (mm)

- Product Type

- Single & Multistart Cutters

- Processing Type

- Multi start helical milling

- Surface Finish

- Smooth, ground finish

- Number of Starts

- 2, 3, 4 or as specified

- Packaging

- Secure, rust-protective packing

- Brand Compatibility

- Universal/Fits most industrial milling machines

- Standards

- Conforms to IS/ISO Industrial Tooling Standards

- Technology

- CNC machined, Heat treated

- Customization

- Available on request

- Edge Profile

- Sharp/Serrated/As required

- Application

- Suitable for milling, grooving, thread milling in metals

- Color

- Silver/Grey finish

- Blade Size

- Customizable as per application

Multistart Cutters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 5000 Pieces Per Day

- Delivery Time

- Days

- Main Domestic Market

- All India

About Multistart Cutters

We offer a qualitative range of Single & Multi Start Cutters that are fabricated using a high-grade raw material such as M35 and tin coated sharpers. These single & multi-start cutters are also customised with regards to shape, size and other specifications as provided by the clients.

Specifications:

- Brand : Malkar

- Design : Customized

- Service : OEM

- Application : Industrial Machinery

- Material : Cr Steel, SS

- Surface : Galvanized

Precision Engineering for Every Industrial Need

These multistart cutters boast cutting-edge CNC machining technology and tailored blade designs, accommodating applications like milling, slot cutting, and thread milling across various metals. Their robust construction and adherence to IS/ISO standards assure reliability and operational safety.

Versatility and Customization Options

Available in diameters from 10 mm to 200 mm and lengths up to 300 mm, our cutters suit different industrial machines and processes. With customizable edge profiles, blade sizes, coatings, and number of starts, they adapt seamlessly to both automated/CNC and manual operations.

Assured Quality and Longevity

Each cutter undergoes heat treatment for enhanced wear resistance and prolonged tool life. Secure, rust-protective packaging and optional PVD/CVD coatings further enhance durability, making these cutters a dependable choice for demanding, high-volume operations.

FAQs of Multistart Cutters:

Q: How do Multistart Cutters improve metal milling processes?

A: Multistart Cutters are engineered for efficient chip removal and high-volume operations, thanks to multiple cutting edges and optimized helical designs. Their sharp or serrated profiles, combined with advanced CNC machining and heat treatment, ensure precise, high-speed milling, grooving, and thread milling with reduced cutting force.Q: What materials and standards do these cutters comply with?

A: The cutters are made of high-grade stainless steel and conform to IS/ISO industrial tooling standards. This ensures both durability and quality, making them suitable for a wide range of industrial metal machining tasks.Q: When should I opt for a customized Multistart Cutter design?

A: Customization is ideal for specialized applications requiring specific blade sizes, edge profiles, coatings, or numbers of starts. If you have unique operational parameters or materials, customized cutters can enhance performance and longevity.Q: Where can these cutters be used, and what machines are compatible?

A: These cutters are universally compatible with most industrial milling, CNC, and general industrial machines used in metalworking industries. They can be used for applications like grooving, slotting, and thread milling in workshops or larger manufacturing plants.Q: What is the recommended application process and machine setup for these cutters?

A: For optimal performance, use the cutter within the specified cutting speed (60120 m/min) and apply correct torque according to your machines capabilities. Both automated/CNC and manual machine setups are supported; proper fixture and coolant usage will ensure high precision and longevity.Q: How do these cutters benefit my industrial operations?

A: Multistart Cutters offer high performance, wear resistance, and long tool life, reducing downtime and tooling costs. Their precision design ensures consistent high-quality results, enhancing productivity and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cutting Tools Category

Spline Hob Cutter

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Spline Hob Cutter

Usage : For Industrial Use

Material : Metal

Diameter : 6300 Millimeter (mm)

Worm Wheel Cutters

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Worm Wheel Cutters

Usage : For Industrial Use

Rack Cutters

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Rack Cutters

Usage : For Machine Use

Material : Steel

Diameter : 10300 Millimeter (mm)

Special Tap

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Special Tap

Usage : For Industrial Use

Material : Others, Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry